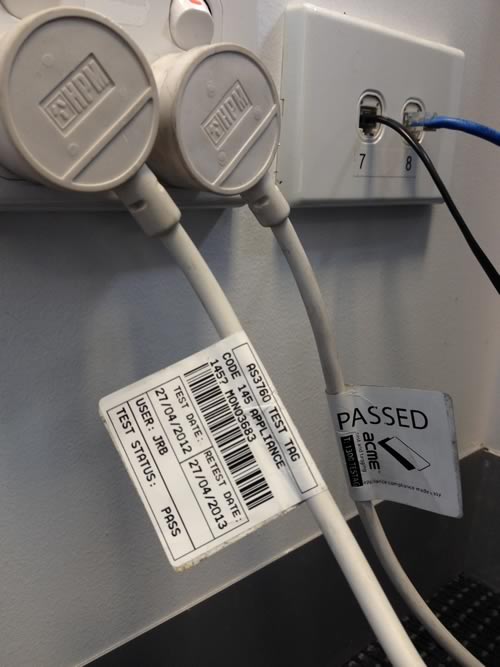

If you plug it in, it gets test and tagged.

That’s a broad rule-of-thumb you can use as a starting point for any test and tag program.

We are taking about are extension leads, computers, power tools, heaters, floor polishers, lamps, battery chargers, laminators, flood lights and more… the range of appliances is wide and varied. (see note below for a more technical explanation)

Some appliances, such as plug-in adaptors and portable safety switches, do not have a flexible supply lead but are still required to be test and tagged.

Appliances that are in a fixed location can be excluded but most of our clients take the safer option and include them in their program ie those bolted to a work bench or floor but have a flexible supply lead and connect to the supply via a power point.

RCDs / safety switches in fixed locations such as switch boards or incorporated into a power board, lead or supply cord also need to be test and tagged on a regular basis. Testing of RCDs also requires checking the trip timeThe trip time is the measurement of the time taken for a Residual Current Device (RCD) to trip (break the circuit). This should occur when a value greater than the rated tripping current of the RCD is detected. The measurement is recorded in milli-seconds. We provide RCD or trip time testing in Melbourne for any business or workplace. More to ensure they are reacting within prescribed limits.

The Standard AS/NZS 3760 includes a number of exclusions so some of your appliances might not need to be done.

Test and tagging is required to be performed on appliances used in workplaces regardless of type or size. This not only includes workplaces were people are engaged in paid employment but also volunteer organisations, not for profit organisations, meeting places such as community centres, club rooms, public places and so on.

Test and tagging can only be performed by a suitably trained and qualified person.

As part of our test and tagging service ACME provides a free on-site workplace assessment service to help you identify what needs to be done and what doesn’t.

Note: Test and tagging is performed on low voltageLow voltage operates within the range of 51V - 1,000V AC or 120V - 1500V DC For test and tagging purposes these appliances present a risk of electric shock. More single phase and poly phase (typically) three phase appliances that connect to the power supply by a flexible cord or connecting device.