Hostile Environment

27/11/2018

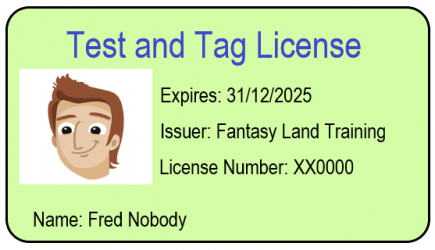

Test and Tag License

13/03/2019RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. More and Safety Switch Testing Requirements On Construction Sites Victoria

“Do we need to get our RCDs on construction sites tested every month?” I get asked this question by lots of tradies and owners of building companies.

The problem is there is a lot of misinformation about the requirements, so in this article I hope to clarify it for you.

The use and testing of Residual Current Devices (RCDs), also known as “safety switches” is set out in the “Industry Standard – Electrical installations on construction sites The Industry Code“.

Example PSOA with RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. More

All portable RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. Mores, such as those located on portable generators and Portable Socket Outlet Assemblies (PSOAs), must be tested using the “press button” method after connection to a socket or before connecting equipment and at least daily when in use. This involves pressing the test button and confirming the RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. More trips “without undue delay”. It is a simple test to confirm the RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. More is operating.

They should also be tested each month using the “applied current” method to ensure they trip within the required maximum current level and response time. To do this special test equipment is required to apply the current and measure the response time.

The same applies to all fixed RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. More, such as those located on permanent switchboards in transportable structures and on construction switchboards; they must be tested every month by operating the test button with the added requirement of the details of the test and the date must be recorded. They should also be tested for tripping current and time each month using the “applied current” method except where the site can demonstrate:

- implementation of a system to ensure all electrical equipment being brought on the site is in a safe condition

- a risk assessment of the operating environment and usage of the RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. More (eg exposure to the environment) justifies a longer duration between tests.

Under these conditions the interval between “applied current” method testing may be up to three months.

Tripping current and time testing can only be undertaken by appropriately qualified persons, including:

- a licensed electrician, or

- a person who has successfully completed a structured training course and been deemed competent in the use of an RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. More tester and interpretation of the results.

It is important to note the words must means it is mandatory, whereas the word should means it is not mandatory but is best practice.

ACME Test and Tagging provides professional RCD testing service for building and construction sites.

This information is general in nature, should be used as a guide only and read in conjunction with the relevant Standard(s), State and/or Federal Legislation, Codes of Practice and Industry Standards specific to your workplace. A proper risk assessment should be under taken before acting on the information provided in this document or any related material. Further information can also be obtained from your local Workplace Authority, Electrical Safety Authority or a suitably qualified persons. This article is copyright protected.