Understanding the Costs of Test and Tag Services: A Comprehensive Guide

20/12/2024Basic Understanding of Test and Tagging

What is test and tag?

Test and tag is the process of inspecting and testing electrical appliances and equipment to ensure they are safe for use. This procedure involves two key steps:

- Testing: The equipment is subjected to a series of electrical safety checks to ensure it is functioning correctly and does not present any risks such as electrical faults or leakage currents.

- Tagging: A label (tag) is applied to the equipment after it passes the test, indicating that it has been tested and is safe for use. A tag is also attached if the appliance is unsafe for use. The tag typically includes the test date, the next test due date (if it passes), and the name of the tester. This process is crucial for preventing electrical hazards in workplaces and ensuring compliance with safety regulations.

Is test and tag a legal requirement in Australia?

Test and tag is a legal requirement in Australia as part of the Work Health and Safety (WHS) Act and AS/NZS 3760. The WHS Act requires employers to ensure the safety of workers, and regularly testing and tagging electrical equipment is part of this duty. Failure to comply with these requirements can lead to significant fines, legal liabilities, and workplace injuries.

Is test and tag a legal requirement in Victoria?

In Victoria, testing and tagging are legal requirements under the Workplace Safety Regulations and AS/NZS 3760. These regulations ensure that electrical appliances and equipment are maintained safely. Depending on the risk level of the work environment, equipment needs to be tested, at a minimum, on a quarterly basis and up to a maximum of every five years

How often is a test and tag required in Victoria?

The required frequency of testing depends on the environment and type of equipment:

- Low-risk environments may only require testing every 5 years.

- High-risk environments (e.g., construction sites, workshops, and factories) typically require testing every quarter.

Some equipment subject to frequent use, such as portable electrical appliances, may require more frequent testing, regardless of the environment. Employers must follow industry-specific guidelines and regulatory standards to maintain safety.

Who needs a test and tag?

Any employer or business owner using electrical equipment in their workplace must conduct test and tag procedures on their appliances. This includes, but is not limited to:

- Offices

- Schools

- Hospitals and healthcare facilities

- Factories and warehouses

- Construction sites

- Retail stores

- Hotels, restaurants, and cafes

The responsibility for test and tagging typically falls on the employer or business owner. If you’re using electrical equipment handled by employees or the public, it’s important to ensure regular testing is conducted to comply with workplace safety laws and prevent accidents.

How long is a test and tag valid for?

The validity of a test and tag depends on the type of equipment and the risk level of the environment:

- In low-risk environments, a test and tag may be valid for up to five years.

- For high-risk environments, the test and tagging is generally required to be renewed quarterly.

The expiry date of the tag will indicate when the equipment is due for re-testing. It’s crucial to keep track of testing schedules and reapply tags to ensure compliance with safety regulations.

How long does it take to test and tag an appliance?

The time required to test and tag an appliance depends on the type of appliance and the testing method. Generally, testing a single appliance can take anywhere from 5 to 15 minutes, depending on the complexity of the equipment and any issues that may arise during testing. For example:

- Simple appliances like portable electrical devices may take 5-10 minutes to test.

- Larger or more complex equipment, such as machinery or power tools, may require more time due to additional safety checks and the need for thorough inspections.

For businesses with multiple appliances, depending on the equipment types and the site’s scale, professional testing services can typically test between 10 to 50 items per hour.

What is RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. More testing?

Residual Current Devices (RCDs), also known as ‘safety switches’, are an important safety device that provides protection against electric shock. RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. More testing is the process of testing the functionality of RCDs, which are safety devices designed to prevent electric shock by shutting off the electrical supply if an imbalance or fault is detected. An RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. More quickly disconnects the power supply when it senses a difference between the live and neutral conductors, ensuring that electrical faults, such as earth leakage, don’t cause harm.

Testing involves simulating a fault condition to verify that the RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. More operates within the specified time limits. This ensures the device’s reliability and effectiveness in protecting users from potential electrical hazards.

How often do RCDs need to be tested and tagged?

RCDs are required to be tested regularly to ensure they are functioning properly and maintaining safety standards. The general guidelines for testing RCDs in Australia are:

- In high-risk environments (e.g., construction sites, factories, and workshops), RCDs should be tested every three months.

- In low-risk environments (e.g., offices and residential properties), RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. More testing is typically recommended every 12 months.

Testing should be done by a competent personA competent person is one who the responsible person ensures has the necessary practical and theoretical skills, acquired through training, qualification, experience or a combination of these, to correctly undertake the required tasks. Source: AS/NZS 3760 More who will check if the RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. More is operating correctly and within the required trip timeThe trip time is the measurement of the time taken for a Residual Current Device (RCD) to trip (break the circuit). This should occur when a value greater than the rated tripping current of the RCD is detected. The measurement is recorded in milli-seconds. We provide RCD or trip time testing in Melbourne for any business or workplace. More. The RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. More must be tagged to indicate when it was last tested and when the next test is due. Regular testing helps ensure protection from electric shock and compliance with safety standards.

For equipment that is rented under a dry hire agreement, where the hirer is responsible for its installation and use, AS/NZS 3760 requires that the organisation renting out the equipment must test and tag it each time it is hired out. However, if the equipment remains under the control of the owner, an annual testing requirement applies.

What is a hostile environmentAn environment where the expected life span of an appliance would be reduced due to factors such as humidity, corrosion, dust, physical abuse etc. It is a key factor in determining suitable retest intervals for an appliance. ( see Table 4 of AS/NZS 3760 ) More? How often do you test and tag in such an environment?

A hostile environmentAn environment where the expected life span of an appliance would be reduced due to factors such as humidity, corrosion, dust, physical abuse etc. It is a key factor in determining suitable retest intervals for an appliance. ( see Table 4 of AS/NZS 3760 ) More is one in which the appliance is normally subjected to conditions that would result in the expected life span of the appliance being reduced due to factors such as:

- Dust

- Corrosion

- Exposure to chemicals

- Humidity

- Physical abuse

For hostile working environments, it is important to retest the appliances and equipment on a regular basis. The only way to assess the environment is by doing a pre-site assessment and understanding the level of risk to the property.

- Low risk – offices, as there is little movement of the appliances.

- Medium risk – packing warehouse or storage facility. Appliances will be moved on occasion.

- High risk – construction, mining, demolition. These environments require quarterly testing and tagging due to the frequent use of appliances.

Standards and Requirements

What is the Australian standard for Tagging and Testing?

The Australian Standard for testing and tagging is outlined in AS/NZS 3760:2010. This standard sets the guidelines for the inspection, testing, and tagging of electrical equipment in the workplace. It specifies the required frequency for testing, the procedures for testing different types of electrical appliances, and the necessary safety checks to ensure compliance with workplace safety regulations. Key aspects of AS/NZS 3760 include:

- The frequency of testing is based on the equipment’s location and usage.

- Correct procedures for performing the tests, such as testing for earth continuity, insulation resistance, and leakage current.

- Tagging requirements include details such as the date of the test, the due date for the next test, and the name of the tester.

What is the Australian Standard for RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. More Testing?

The Australian Standard for RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. More testing is specified in AS/NZS 3760:2010 for testing electrical equipment, which includes the periodic testing of Residual Current Devices (RCDs). This standard provides detailed instructions on how to perform RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. More tests to ensure they function correctly. The testing process ensures that RCDs can detect leakage currents and shut off the power in the event of an electrical fault.

The key points for RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. More testing according to the standard are:

- RCDs should be tested for their trip timeThe trip time is the measurement of the time taken for a Residual Current Device (RCD) to trip (break the circuit). This should occur when a value greater than the rated tripping current of the RCD is detected. The measurement is recorded in milli-seconds. We provide RCD or trip time testing in Melbourne for any business or workplace. More and sensitivity.

- RCDs must be tested with a simulated earth leakage current to verify their operation under fault conditions.

- Functional testing of RCDs must be done at intervals based on the risk level of the environment, typically every 6 months for high-risk areas and 12 months for low-risk environments.

What is required to be on an appliance nameplate?

The appliance nameplate provides essential information about the electrical appliance to ensure safety and compliance. According to Australian standards, the following information is required on an appliance nameplate:

- Manufacturer’s Name and Address – Identification of the manufacturer or importer.

- Model Number and Serial Number – Helps identify the specific appliance and trace its details.

- Voltage Rating – Indicates the operating voltage of the appliance (e.g., 240V for most domestic appliances).

- Current Rating (Amps) – Specifies the amount of electrical current the appliance draws.

- Power Rating (Wattage) – Indicates the amount of power the appliance uses, usually in watts (W).

- Frequency (Hertz) – The frequency of the electrical supply, usually 50Hz in Australia.

- Safety Markings – Relevant safety symbols, such as the ‘tick’ for compliance with Australian safety standards.

- Insulation Class – Indicates the insulation type used, ensuring that it is appropriate for the appliance’s application.

This information is essential for safety inspections, compliance, and helping technicians perform the correct testing and maintenance on the equipment.

What Needs Testing

Which appliances/equipment should be tested and tagged?

Test and tagging is a safety measure required for all workplace appliances, including extension leads, computers, power tools, heaters, floor polishers, and more. If it gets plugged in, it gets tested and tagged—that’s the rule of thumb.

For test and tag purposes, electric appliances are classified as Class I (earthed) or Class II (double-insulated).

- Class I – Earthed appliances, such as kettles, irons, and toasters, which have an earth connection for added safety.

- Class II – Double insulated appliances, identified by a square-within-a-square symbol or labelled ‘Double Insulated.’ Examples include most electric drills and hair dryers.

While fixed-location appliances can sometimes be excluded, most businesses opt to include them for safety. Certain items, like plug-in adaptors and RCDs, must always be tested, with RCDs requiring trip-time checks.

AS/NZS 3760 outlines specific exclusions, but testing applies to all workplaces, including volunteer and non-profit organisations.

Do new appliances need to be tested and tagged?

In Australia, the responsibility for the initial electrical safety of new equipment lies with the supplier.

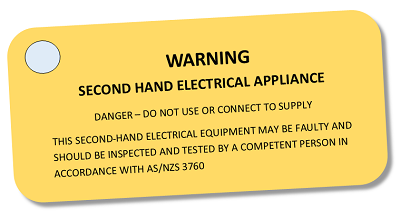

While newly purchased equipment does not need to undergo testing, it must still be visually inspected for any visible damage and appropriately tagged. However, if you intend to resell second-hand equipment, it is essential to inspect, test, and label it correctly.

For new equipment, the correct tag to use is a “New to Service” tag. This tag indicates that the item has not been tested and will require testing at a later date.

The New to Service test tag should include the following details:

- Wording: “New to Service”

- Date of entry into service

- The next scheduled test date

- Statement: “This appliance has not been tested in accordance with AS/NZS 3760”

To remain compliant with the AS/NZS 3760 Standard, ensure that all new equipment is labelled with a ‘New to Service’ test tag.

Do extension cords need to be tested and tagged?

Any electrical device with a cord, cable, and plug operating above 50V must be tested and tagged. This applies to equipment such as extension leads, cord sets, and portable RCDs.

Electrical appliances fall into two main categories:

- Earthed appliances: These rely on an earth connection for safety and include items like kettles, toasters, and irons.

- Double insulated appliances: Designed with additional insulation instead of an earth wire, examples include drills and hair dryers.

While routine testing and tagging are required for all electrical appliances, newly purchased equipment is an exception. Instead of full testing, new items must be visually inspected for any signs of damage and tagged with their service entry date and the next scheduled test date.

Qualifications and Training

Who can test and tag?

In Australia, test and tag can be carried out by individuals who are competent and qualified to do so. Typically, this includes:

- Licensed Electricians—The most common person responsible for conducting test and tag procedures is a licensed electrician. They have the necessary expertise to test electrical appliances and ensure they meet safety standards.

- Competent Persons—Individuals who have undergone specific training in test and tag procedures, often in a certified training course. Although they are not licensed electricians, these trained persons are considered competent to perform testing and tagging. They must adhere to AS/NZS 3760 standards to ensure the process’ safety and effectiveness.

- Employers or Business Owners—In some cases, employers or business owners may be responsible for ensuring the correct test and tag process is carried out. However, they must ensure that qualified personnel perform the tests.

What qualifications do you need to test and tag?

Although there is no formal or recognised system for licensing test and tag technicians in Australia, you must have the appropriate qualifications or have completed a relevant course for testing and tagging.

While a full electrical licence isn’t necessary, a person must undergo formal training in test and tag procedures to be deemed a ‘Competent Person’. This training includes a short accredited course that covers the relevant testing methods, safety standards, and AS/NZS 3760 compliance.

It’s essential to have a basic understanding of electrical safety, the ability to use testing equipment and knowledge of appropriate labelling procedures. Some training courses may also include practical testing to ensure competence.

Do you need a license to test and tag?

Technically, you don’t need a licence to perform test and tagging if you are a competent personA competent person is one who the responsible person ensures has the necessary practical and theoretical skills, acquired through training, qualification, experience or a combination of these, to correctly undertake the required tasks. Source: AS/NZS 3760 More who has completed the required training. However, if you are a licensed electrician, you already have the qualifications to conduct a test and tag without any additional certification.

That said, if you are working in a commercial or high-risk environment, such as a construction site or industrial setting, the person performing the tests may need to demonstrate their competency through proper training, even if they are not licensed electricians. Employers should ensure they meet all safety and regulatory requirements for their specific industry.

Testing Process and Methods

What are the four steps in test and tag?

The test and tag process follows a standard procedure to ensure electrical appliances are safe to use. The four steps are:

- Visual Inspection: The first step is to visually inspect the appliance for any visible signs of damage, such as frayed cords, exposed wires, or cracks. This helps identify any obvious safety hazards before proceeding with electrical testing.

- Testing for Electrical Safety: The next step is to use specialised testing equipment to check the appliance’s electrical integrity. This includes testing for earth continuity, insulation resistance, and leakage current. These tests ensure the appliance is not electrically faulty and meets the required safety standards.

- Tagging the Appliance: Once the appliance passes the electrical tests, a tag is attached to indicate that it has been tested and is safe for use. The tag typically includes information such as the test date, the next test date, and the tester’s name.

- Documentation and Record-Keeping: The final step is recording the test results for future reference. The technician should record details such as the inspection date, type of appliance and test readings taken. This information is vital for recording repairs or modifications to electrical equipment and provides evidence in cases of accidents caused by faulty equipment or improper testing.

What tools can you use to test a tag?

To test appliances and ensure they are electrically safe, the following equipment is used in accordance with Australian standards AS/NZS 3760.

- Portable Appliance Tester (PATAcronym for Portable Appliance Tester – a portable device used for electrical testing of appliances. More)

A portable appliance tester, or PATAcronym for Portable Appliance Tester – a portable device used for electrical testing of appliances. More, is the primary tool for testing electrical equipment. It consists of a tester and probe that measure electrical current, grounding, insulation resistance, and polarityPolarity refers to the wiring protocol for electrical appliances. See AS/NZS 3760:2010 Appendix C. More. It also includes features like an earth continuity checker and an insulation resistance checker.

- Multimeter

A multimeter is also commonly used to measure continuity, voltage, and resistance. It’s useful in testing earth continuity and insulation resistance in appliances. - Earth Leakage Tester

An earth leakage tester is used to test for leakage currents that could indicate an electrical fault. It measures how much current flows to earth through the appliance and ensures it is within safe limits. - Insulation Resistance Tester

This device checks the insulation resistance of an appliance to make sure no current is leaking through its outer casing. It helps detect faulty insulation that could pose an electric shock risk. - RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. More Tester

If the appliance is connected to an RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. More (Residual Current Device), an RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. More tester is used to check its performance, ensuring it trips when the leakage current exceeds safe levels.

What are the different coloured tags that can be used on appliances?

Test and tag colours identify the last date electrical equipment was tested. Colour coding helps quickly identify tested or overdue appliances by cycling through different colours at each retest.

For example, a six-monthly interval could use BLUE, GREEN, and RED tags in rotation. This system makes it easier to:

- Spot missed appliances (previous colour tags indicate overdue items).

- Ensure equipment is safe to use.

- Conduct quick workplace checks for overdue items.

Different environments may require different retest intervals, so workplaces often assign specific colours accordingly. While AS/NZS 3760 does not mandate colours, AS/NZS 3012 (for construction sites) requires a four-colour system for three monthly retests. NSW has different rules, requiring monthly retesting. Appliances moving between sites—especially across NSW borders—must meet local tagging requirements. Failing to use the correct colour could mean being unable to use equipment on-site. Always check state-specific regulations to ensure compliance.

What are the test and tag colour codes in VIC for construction sites?

In Victoria, AS/NZS 3012 outlines the requirements for testing and tagging electrical appliances used on construction/building sites. Portable electrical appliances used on-site must be retested every three months, accompanied by a corresponding colour coding system. According to AS/NZS 3012:2010, the following tagging regulations apply in Victoria (VIC):

- Red Tag – December, January, February

- Green Tag – March, April, May

- Blue Tag – June, July, August

- Yellow Tag – September, October, November

MISC

Can I do the test and tag by myself?

You can test and tag appliances yourself if you are deemed a ‘Competent Person’ . To be considered competent, you need to undergo a certified training course in test and tag procedures, which covers the correct testing methods, safety regulations, and standards such as AS/NZS 3760. However, if you are not a licensed electrician, you may only be able to perform test and tag duties on low-risk equipment or in specific situations where the law allows it. For more complex or high-risk equipment, it’s recommended to hire a licensed electrician.

Do you need to test and tag if you have RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. More?

Even if your workplace or equipment is equipped with a Residual Current Device (RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. More), you still need to perform a test and tag on electrical appliances. While an RCDRCD is an acronym for Residual Current Device. They are also known as safety switches. RCDs are designed to protect people from electric shock. More provides an additional safety measure, it does not eliminate the need for testing the appliances themselves. Test and tag ensure that all equipment is functioning properly, safe to use, and meets the required safety standards. RCDs must also be tested regularly (typically every 3 months for high-risk environments) to ensure they are working effectively

How much does a test and tag cost?

The cost of test and tag services depends on the contractor’s pricing structure. Here are the four most common methods:

- Per Tag Rate – This is the most widely used pricing method, where you pay a fixed price per appliance tested and tagged.

- Pros: Easy to calculate, transparent, and cost-effective for businesses with a moderate number of appliances.

- Cons: Costs can add up for businesses with a high volume of appliances. Some contractors may have a minimum tag requirement or additional service fees.

- Hourly Rate – The contractor charges based on the time taken to complete the job.

- Pros: Can be cost-effective for small-scale jobs with fewer appliances.

- Cons: If the job takes longer than expected or the contractor works inefficiently, costs can quickly increase. Harder to estimate final expenses in advance.

- Combination Rate – A hybrid approach that includes a lower per tag rate combined with an hourly fee.

- Pros: Provides flexibility and ensures contractors are fairly compensated while keeping costs manageable.

- Cons: More complex to calculate and may require estimates before work begins.

- Fixed Rate – A predetermined total price for the entire job, usually quoted after an initial assessment.

- Pros: Predictable, making budgeting easier. No surprise costs as long as the job scope remains unchanged.

- Cons: Contractors may inflate quotes to cover unforeseen challenges. If the job is completed quickly, you might end up overpaying.

Hidden Costs to Watch For

While many contractors provide transparent pricing, some may use “trickle pricing,” where additional fees are added later, inflating the final bill. Be mindful of travel fees, invoicing and statement fees, per-line fees in reports and inventory management fees.

What are some of the penalties for not testing and tagging?

Non-compliance with test and tagging regulations can result in severe penalties, both financial and legal. The consequences for failing to meet these safety standards can include:

- Financial Penalties: Businesses that do not adhere to test and tag requirements can face significant penalties. For example, in Victoria, businesses/sole traders/individuals may incur penalties from WorkSafe Victoria at a minimum of $197.59 per credit for failing to comply.

- Legal Action: In cases where non-compliance leads to injury or fatalities, businesses may face prosecution, which can result in heavy fines or, in extreme cases, imprisonment for those responsible for workplace safety.

- Insurance Implications: If an electrical incident occurs due to untested or untagged equipment, businesses may find themselves without coverage, as insurance claims can be denied. Additionally, businesses could be held financially liable for damages, leading to considerable loss and potential damage to their reputation.

Failure to follow test and tag regulations not only puts workers at risk but can also bring serious financial and legal consequences for the business.