As part of the test and tagging process, a tag displaying the overall PASS / FAIL outcome needs to be attached to the appliance. This tag must include the date it was checked and when it is due for retesting plus other information.

A colour coded system can be used, but in most situations, is not mandatory.

The idea behind using a colour coding system for your tags is it makes it quicker and easier to identify appliances that were checked on a certain date or are overdue for retesting. A simple colour coding system cycles through a number of different coloured tags over several rounds of retesting.

For example if you use six monthly retest intervals you could start by applying BLUE tags. When it comes time to retest all the appliances you could then apply GREEN tags and after that, RED tags and so on. There are several advantages in using a simple colour coding system like this;

- When you finish doing a round of testing it is easy to identify any appliances you may have missed because they would have the previous colour tags still on them.

- It makes it easier for any person about to use the appliance to identify if it is OK to use the appliance – if the tag has the previous colour then it is overdue and shouldn’t be used, if it has the current colour it should be OK to use.

- If your role is to oversee the test and tag program in your workplace, then it is easy to do a “walk through” and identify if any overdue appliances are still in service or being used.

Many workplaces have a number of different environments that requires different retest intervals to be applied. You can create a colour coding system that assigns a series of colours to the different intervals used in different environments. For example the six monthly interval could cycle through BLUE, GREEN & RED whilst the twelve monthly interval could cycle through WHITE & ORANGE. Try to avoid periods where the same colour is being used at same time.

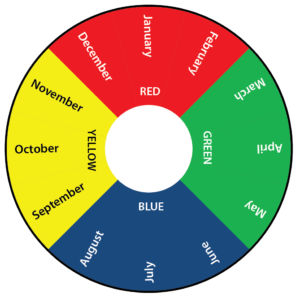

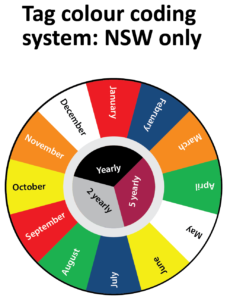

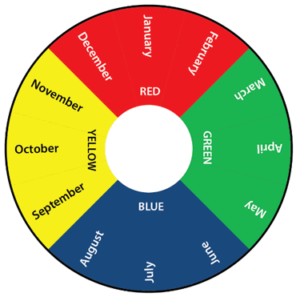

The choice of colours you use is up to you as the Standard AS/NZS 3760 doesn’t have any specific requirement on what colour tags should be used. There is however a clause that informs the reader some other standards do have specific colour coding systems. One of them is AS/NZS 3012 (Electrical Installations – Construction and Demolition Sites) which uses a four colour system for the three monthly retest interval. This is what is commonly known as the colour coding system for “builders tools”. It is used in Victoria and all other states except for NSW which has adopted a different system due to their requirement for monthly retesting.

Problems can arise where an appliance is tested and tagged with the correct interval and colour coding system for their State and is then moved to a workplace inside or outside NSW; this is especially so for mobile workers entering and exiting NSW work sites.

When setting up your test and tag program a colour coding system can deliver many benefits, however if some or all of your appliances will be used off-site, then you need to check if there are any specific colour coding requirements you need to implement as you wouldn’t want to arrive on-site and then be told you can’t use your tools because they have the wrong colour tags on them.

What are the Test and Tag Requirements On Building & Construction Sites Victoria

Portable electrical appliances used on Victorian construction sites must be test and tagged at intervals no greater than every three months and a colour coded system for the tags must be followed.

Construction sites are considered to be a hostile environment and the therefore appliances on these sites are typically subjected to greater wear and tear that can lead to increased risk of electric shock to the user and other workers.

This graphic shows the tag colour system used for the three monthly retest interval schedule.

An easy way to remember the periods is each colour corresponds to one of the four seasons.

There is differing opinion as to when the retesting of the appliances is actually due.

Those attending unionised sites will usually find they are required to have their appliances undergo test and tagging within the week either side of the change-over point for the new colour. For example during the last week of November and first week of December

WorkSafe Victoria have indicated their requirements for retesting are satisfied provided;

- the appliance has been test and tagged within the last three months

- the correct tag colour for the period it was last checked during is used

Requirements for the testing of fixed and portable Residual Safety Devices ( RCDs ) are slightly different. There are two methods that apply;

Push Button Test

The “push button” test involves pressing the test button and checking the RCD trips without “undue delay”.

This must be performed daily on portable RCDs and monthly for fixed RCDs

Trip Time Test

This test measures the actual trip time of the RCD and requires the use of specialised RCD test equipment

This must be performed monthly on portable and fixed RCDs however subject to meeting certain condition the interval can be extended to three monthly.

NOTES

Appliances and RCDs can be test and tagged by either

- A licensed electrician

- A “competent person”

Requirements vary between States / Territories and therefore tags complying with Victorian requirements may not be recognised even though they are current. When travelling across the border or to other jurisdictions, it would be wise to check prior to your departure.

References:

Industry Standard Electrical installations on construction sites (2011).

Standard AS/NZS 3012

Standard AS/NZS 3760